Thermal Imaging: Optimizing Performance and Safety Measures

With the development of technology, thermal imaging has completely revolutionized the operations of numerous industries. These devices are increasingly used in everyday life, from construction to medical to industrial fields, and thermal imagers provide accurate and reliable temperature measurements and analysis results with their unique capabilities. However, to realize the full potential of thermal cameras, it is not only necessary to understand how they work but also to follow some specific precautions. Doing so ensures that these instruments maintain optimal performance and extend their service life. This article elaborates on a series of measures to improve measurement accuracy, optimize performance, and ensure user safety. Following these recommendations will not only help professionals fully utilize the potential of thermal imaging, but also enable them to make more informed judgments and decisions based on accurate and reliable thermal data.

Firstly, Observing precautions helps protect equipment from external environmental influences that may interfere with its performance, rendering it unable to accurately detect heat sources or conduct effective data collection. Therefore, by taking the necessary precautions, they can be ensured to operate at maximum efficiency over a long period.

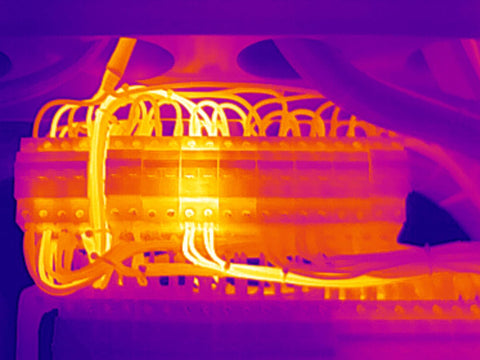

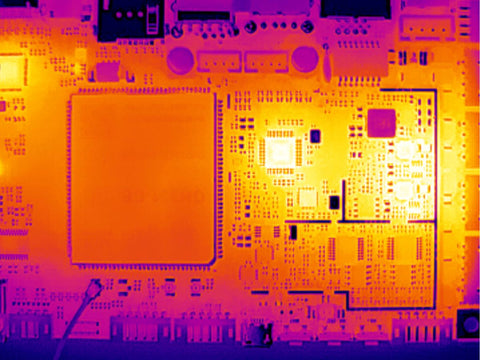

Secondly, following these precautions also maximizes the reliability of the obtained data. This accuracy is critical in many applications: identifying overheating elements in electrical systems, assessing energy losses in buildings, and many other situations. Without proper adherence to preventive measures, the accuracy of the data obtained will be affected.

In addition, thermal cameras are often used to deal with a variety of potentially hazardous environments. For example, safety precautions are especially important when conducting inspections in high-pressure areas. Similarly, when used in an industrial environment, it is also necessary to strictly comply with safety regulations to protect the safety of the operator. In summary, through preventive measures, thermal cameras can provide accurate and reliable data in any situation, while protecting users from the threat of accident or injury.

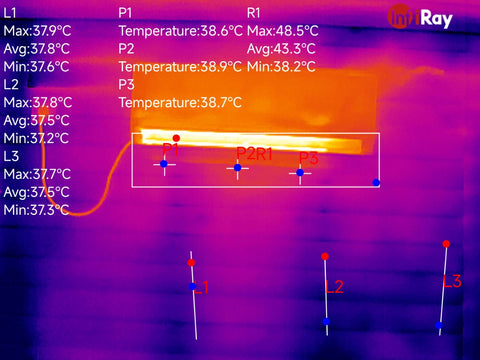

Maintaining an appropriate measurement distance is crucial for capturing accurate thermal images, as slight deviations can lead to severe distortion of temperature information within the images. When operating a thermal camera, users must strictly follow the guidelines provided by the camera manufacturer. At the same time, the focal length adjustment of the lens should also be carefully adjusted to ensure that the focus matches the true size of the subject, to avoid the problem of detail loss and image blurring caused by too close or too far focal length. This not only helps to capture a clear subject but also enables accurate temperature analysis of the subject to obtain reliable data results, which provide important references for subsequent research or decision-making.

When conducting outdoor thermal imaging measurements, strong sunlight will affect the performance of the equipment. Due to its high sensitivity and temperature-sensing ability, direct sunlight can interfere with the normal operation of the sensor, resulting in data distortion and even the inability to capture images. To minimize such interference, it is recommended that users avoid operating the camera under direct sun conditions, and secondly, try to avoid exposing the camera lens to strong light for a long time.

Through these methods, users can improve the reliability of thermal imagers and ensure that accurate and reliable thermal images are obtained to better analyze and evaluate thermal characteristics in the environment. With the popularity of infrared thermal imaging technology, it has gradually penetrated from the high-end field into various corners of daily life. Therefore, understanding and implementing these best practices is key for everyone who uses infrared thermal imaging tools to ensure the maximum utility of this technology.